Environmental responsibility

Operational efficiency reduces emissions

In 2022, traditional trade flows changed drastically due to Russia’s invasion into Ukraine. As a result, distances sailed especially by our larger tonnage increased significantly.

In 2022, the company’s fleet consisted on average of 47 vessels but the number of vessels decreased to 41 at the end of the reporting period due to redeliveries of time-chartered vessels. The emissions decreased partly due to lower average number of vessels in the fleet but also due to increased operational efficiency which is clearly seen in the improved ballast ratio as well as CO2-efficiency, which improved by 13%. Overall, the company’s CO2-emissions decreased by 8.5 percent and the total use of fuel measured in megawatt hours by 8.7 percent.

As virtually all of our annual carbon dioxide emissions derive from vessel operations, utmost attention is paid to optimise the operation of vessels. Our ship operators work closely with vessels to discuss the most optimal speed for each passage and to optimise the amount of cargo loaded onboard.

ESL Shipping has the ISO 14001 certified Environmental Management System. In 2023, the target is to extend the ISO 14001 certification to cover AtoB@C Shipping’s operations as well. In addition, the group holds EcoVadis Silver rating from its sustainability work.

Growth in a ship’s underwater hull is a factor that can significantly increase a vessel’s fuel consumption. No harmful antifouling or TBT-based paint has been used in our owned vessels for years and instead, divers clean vessel hulls frequently. To further help determine the correct timing for hull cleaning, we have acquired an underwater drone for use at our Raahe depot. With the drone, vessel’s crew and our maintenance staff ashore can easily assess the condition of the hull growth.

Waste management onboard follows international and national regulations. Each vessel has a garbage management plan, which describes how different types of waste are handled onboard. All waste generated onboard is sorted and delivered to reception facilities ashore. As our vessels mainly trade in the contract traffic, crews have good knowledge about the ports and the recycling facilities there. Garbage statistics are collected from vessels on a monthly basis for further analysis. The aim is to reduce the amount of waste generated onboard and to minimise the amount of mixed waste.

All vessels equipped with BWTS

The aim of the ballast water treatment systems (BWTS) is to prevent foreign organisms from transferring into other sea areas in the vessel’s ballast water tanks. Ballast water is essential for all types of vessels to ensure the stability and correct trim of the vessel. The last four owned vessels were equipped with ballast water treatment systems during their scheduled dockings in 2022 meaning that our whole fleet is now compliant with the upcoming regulations.

In addition to ballast water, there are several other waters that are handled onboard. Oily bilge and sludge waters are always discharged ashore. Grey water, i.e. water from showers and taps is partly discharged ashore and partly overboard depending on the arrangements onboard a vessel. Black water, i.e. sewage from toilets is either discharged to the shore or discharged to the sea after going through a treatment system. While we aim to significantly increase the amount of wastewater delivered ashore, the challenge is that many of our older vessels do not have separate tanks to store black and grey waters. This is especially the case with our smaller vessels where there is not enough tank capacity to store the water. Another challenge is that many ports do not have established reception facilities for waste water.

Generally, cargo hold washing water containing non-harmful cargo residues can be discharged to the sea whereas hold-washing water containing harmful cargo residues must always be discharged to shore reception facilities. In a special area, such as the Baltic Sea, discharge to the sea is only permitted if both of the ports in a voyage are in the special area and there are no adequate reception facilities and the residues are non-harmful to the marine environment.

In 2022, we registered three (2021: 3) minor oil spills. As a result of these incidents, slightly less than 20 litres of oil were released into the environment. These were handled properly and resulted in no further consequences from the authorities.

Calculation of carbon footprint

There are several ways to calculate carbon footprint from shipping. The below example aims to provide an understanding of how the emissions of a sample voyage would look like with different calculation methods.

In this report, we measure our green house gas (GHG) emissions in carbon dioxide (CO2) as well as carbon dioxide equivalent (CO2e). CO2 is a major contributor to climate change and is the most commonly reported greenhouse gas, making it a critical metric for understanding our impact on the environment. Carbon dioxide equivalent (CO2e) on the other hand is a metric used to express the total impact of GHGs in terms of the amount of CO2 that would have the same warming effect. This allows for a more comprehensive assessment of a company's greenhouse gas emissions, as different gases have different warming potentials.

By measuring our total emissions, we can understand our impact on the environment and identify areas where we can improve. By measuring CO2 and CO2e efficiency, we can benchmark ourselves against the industry and analyse if we are operating in an efficient manner. The efficiency is calculated by dividing the emissions by the transport work (ton-miles) and hence provides a scalable KPI to follow.

Another distinction is made between tank-to-wake (TTW) and well-to-wake (WTW) emissions. TTW refers to the emissions directly caused by the burning of the fuel. WTW additionally measures the "upstream emissions", referring to the greenhouse gas emissions associated with the extraction, production and transportation of the fuel. These emissions occur throughout the entire supply chain, from the extraction of raw materials to the delivery of the finished energy product and finally the consumption. We recognise the importance of understanding and reducing our well to wake emissions, as they give a comprehensive metric for the total environmental effect depending on the fuels used.

What does all this mean in practice?

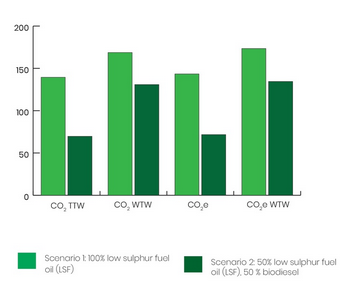

Next, we provide an example calculation displaying how the same voyage can look quite different depending on the reporting style. The difference between magnitudes of CO2 and CO2e and how the TTW versus WTW reporting affects the voyage depending on the fuel types used will be analysed in the following section.

The example voyage is from Luleå to Oxelösund. The numbers used in this example are based on the averages of 15 actual similar voyages. In Scenario 1 the voyage is performed by using only low-sulphur fuel oil (LSF) while in Scenario 2 half of the consumed fuel was biodiesel.

The emission factors used in the calculations of the above table are based on the commonly used GLEC 2.0 framework. It is important to note that not all NOx (significant GHG especially in the maritime industry) are calculated in this framework, as NOx measurement is quite complex and dependent on the engine types and how they are operated. The actual CO2e would be higher, but no widely recognised framework exists which could be utilised to include them.

As seen from the chart, CO2e is not significantly different from CO2. However, the WTW numbers differ quite significantly from the TTW numbers, especially when looking at Scenario 2. This is because the TTW emissions of biodiesel are practically nothing, but producing them causes emissions. They still come out on top as significantly more environmentally friendly options compared to fossil fuels, but the gap is smaller.

Virtual Arrival reduces emissions by 24%

Virtual Arrival has changed the traditional way of working and provides an opportunity to reduce emissions.

The basic idea of Virtual Arrival is to reduce a vessel’s speed to meet revised arrival time if it is known that the berth will not be free on arrival. Regardless of the actual arrival time, the vessel retains its place in the line-up based on the arrival time in normal service speed.

In shipping, vessels are normally scheduled to meet certain arrival times at a port in order to start time counting whether the berth is actually free on arrival or not. If the assigned berth is not free, the vessel will drop anchor on arrival and tender notice from the roads. In other words, the vessel will sail the whole passage with normal speed even though it is known that there will be delays at berthing.

In 2022, Virtual Arrival was applied in the traffic between Luleå and Oxelösund together with SSAB and Port of Oxelösund. The results are astonishing: CO2-emissions were reduced on average by 24 percent, which is the equivalent to around 4.3 million kilometres with a petrol car.

Positive experiences have also contributed to the international attention given to the concept. Finnish traffic management company Fintraffic has chosen Virtual Arrival as one of its key projects in 2023. The concept was also one of the initiatives in the Green Shipping Challenge that was launched in the UN Climate Change Conference (COP27) in Egypt.

We continue to work with our clients to extend this practice to other trades in 2023.

Renewable marine fuel available across the fleet

The ISCC PLUS certified marine fuel enables up to 80 percent reduced greenhouse gas emissions over the life cycle compared to fossil fuels and zero tank to wake emissions.

From mid-2022, our customers have had the possibility to reduce the emissions of their sea transports by opting to use Neste Marine 0.1 Co-processed marine fuel. The fuel is produced at Neste’s refinery in Porvoo, Finland, where part of the fossil raw materials have been replaced with renewable raw materials in the conventional refining process.

The drop-in fuel can be taken into use without any fleet modifications as it has a similar composition to conventional bunker fuels. The ISCC PLUS certified marine fuel enables up to 80 percent reduced greenhouse gas emissions over the life cycle compared to fossil fuels and zero tank to wake emissions.

“The co-processed marine fuel is something we have been waiting for a long time. ESL Shipping is committed to leading the way in reducing greenhouse gas emissions of the maritime industry and we are now fortunate to be able to use this low-emission alternative without having to do any fleet modifications. We believe this is the right thing to do and I am convinced that here in the Nordics we are well-positioned to show the way for the global maritime industry,” says Mikki Koskinen, Managing Director of ESL Shipping.

As the lifespan of a vessel can extend from 25-30 years, most of the existing vessels will sail in the company’s fleet for many years to come. Neste co-processed marine fuel provides a cost-effective way to extend the lifespan of our fleet and provides our clients a convenient way to reduce the emissions of their shipments regardless of the vessel type.