Environmental responsibility

Over 90% of the world’s trade is carried by sea and international vessel traffic which accounts for 2.6% of global emissions. Sea transportation is vital for Finland and Sweden which are the group’s core market areas. Around 90% of the imports and exports from both countries is carried by sea.

Our near and long-term climate targets are validated by SBTi

The Science Based Targets initiative (SBTi) has approved ESL Shipping’s near and long-term emission reduction targets as the first company in the general cargo segment. Approval means that the targets align with the latest climate science to limit global warming to 1.5 degrees Celsius, which is in line with the Paris Agreement.

We are committed to reduce our well-to-wake GHG emissions by 59.6% per ton-nautical mile by 2030, which equals a 47.1% absolute reduction. In the long term, we are committed to achieve net zero emissions by 2040 and to reduce well-to-wake emissions by 97.8% from the 2023 base level.

Although outside of the scope of the GHG Protocol, SBTi requires the use-phase emissions of transported fossil fuels to be included in the target boundary. We are committed to discontinue the transport of fossil fuels, such as energy coal, latest by 2030 and to reduce the emissions from the use-phase of transported fossil fuels by 100% by 2030 from the 2023 baseline.

“This milestone reflects our deep commitment to climate action and the transformation of maritime logistics. Through fleet renewal, operational efficiency, and the increased use of renewable fuels, we are not only reducing emissions but also setting a new standard for sustainable shipping. Our transition plan is ambitious, but we are determined to deliver on it,” says Mikki Koskinen, Managing Director of ESL Shipping.

ESL Shipping’s approved science-based targets

Overall net-zero target

- ESL Shipping commits to reach net-zero greenhouse gas emissions across the value chain by 2040.

Near-term targets

- ESL Shipping commits to reduce well-to-wake scope 1 and 3 GHG emissions from general cargo and bulk carrier shipping operations 59.6% per tonne nautical mile by 2030 from a 2023 base year, equivalent to a 47.1% absolute reduction.*

- ESL Shipping also commits to reduce absolute scope 3 GHG emissions from use of sold products for distributed fossil fuels 100% by 2030 from a 2023 base year.

Long-term targets

- ESL Shipping commits to reduce well-to-wake scope 1 and 3 GHG emissions from general cargo and bulk carrier shipping operations 97.8% per tonne nautical mile by 2040 from a 2023 base year, equivalent to a 97.1% absolute reduction.*

- ESL Shipping also commits to maintain 100% absolute scope 3 GHG emissions reductions from use of sold products for distributed fossil fuels from 2030 through 2040 from a 2023 base year.

- ESL Shipping Ltd further commits to reduce all remaining absolute scope 3 GHG emissions 90% by 2040 from a 2023 base year.*

*The target boundary includes land-related emissions and removals from bioenergy feedstocks.

Our roadmap towards net zero

Emission reductions come from two main sources: investments to new, low-emission vessels equipped with the latest technology and the capability to use different low-emission or fossil-free fuels. With the delivery of 12 green coasters and four 17,000 dwt methanol-enabled vessels, we can renew the fleet by divesting older, less efficient tonnage. With an additional six eco vessels entering our time-chartered fleet between 2025 and 2027, we have a robust plan for renewing the chartered fleet as well.

The majority of the reduction comes from the use of renewable fuels. Uptake of low-emission fuels comes partially from regulations such as FuelEU Maritime and the EU Emission Trading System, but also from the clients who want to reduce their Scope 3 emissions. Reaching our 2030 and 2040 targets is highly dependent on the availability and cost of alternative fuels.

By having oil, gas and methanol-powered vessels in the fleet towards the end of 2030, we have alternative supply paths to source renewable fuels. Currently, we are in discussions with several suppliers for the supply of green methanol for our methanol-enabled newbuildings, which will be delivered between Q3/2027 and Q2/2028. We have already successfully demonstrated the potential of drop-in fuels such as biogas and renewable marine diesel.

Our roadmap consists of three pillars

Best possible ship design & technology

A critical part of the green transition is access to the best available ship design and power train capable of shifting to drop-in low-emission and fossil-free fuels when they are available. We have recently made significant investments in line with this strategy. In October 2024, we ordered four 17,000 dwt methanol-enabled general cargo vessels and have received eight out of twelve 5,400 dwt plug-in hybrid coasters equipped with battery packs and shore power connection.

We have also signed a long-term time charter of six low-emission 5,900 dwt vessels, which will join the fleet between 2025 and 2027. In addition, we own and operate the world’s first LNG-powered bulk carriers, Viikki and Haaga, which are equipped with shore power connections and can operate almost fossil-free using LBG.

Industrial-scale availability of renewable fuels

We are working with various partners to build industrial-scale availability of renewable fuels in partnership with leading Scandinavian suppliers. For example, we were the first Finnish shipping company to use the new co-processed marine fuel oil produced by Neste, enabling up to an 80% reduction in lifecycle carbon dioxide emissions.

We are involved in the BotniaLinkH2 project as the first customer-side stakeholder. The project aims to establish an e-fuel hub in Luleå to produce hydrogen-based marine fuels.

Client commitment

An integral part of the roadmap is customers who share a common future vision and interest in low-emission shipping. In 2024, we reached two significant agreements with clients. EFO has agreed to use at least 10% of renewable fuel in its shipments, and with Metsä Forest, we target a 30% reduction in the CO2 efficiency of the wood shipments by 2030.

Furthermore, SSAB and the Port of Oxelösund have played a pivotal role in the launch of Virtual Arrival, which has enabled a 24% reduction in CO2 emissions in applied voyages between Luleå and Oxelösund.

-1-1.jpeg?width=939&height=939&name=Green%20Handy%20rendering%203-2025%20%20(1)-1-1.jpeg)

Larger vessel reduces emissions per cargo ton

A ship is the most environmentally friendly alternative for transporting large quantities of cargo. For instance, one Eira-size 20,000 dwt vessel is the equivalent of around 1,100 trucks with cargo capacity of 18 tons.

In general, smaller vessels consume more energy for the same transport work. The consumption per cargo ton transported with a coaster is on average three times higher than on our LNG powered vessels Viikki and Haaga.

One of the easiest ways to decrease carbon footprint is the use of bigger ships and to slow down their speed. However, it must be recognized that this is not possible for all of our clients and industries due to lot sizes and restrictions in harbours.

Smaller parcels will be shipped and small vessels will be trading also in the future. In order to provide an environmentally superior alternative in the smaller vessel class, we are currently building twelve new, extremely energy efficient 5,400 dwt plug-in hybrid vessels of which two thirds are already in operation.

Emissions to the water

In the normal operation, vessels produce different wastewaters. Grey and black water are related to the crew living onboard whereas hold washing water is related to preparing the cargo hold for a next cargo. All on all, our vessels delivered 37.4% of their wastewaters to shore in 2024. In addition, there is ballast water which is used to provide the required stability for the vessel and to achieve optimal trim. Oily bilge and sludge waters are always discharged ashore.

Black and grey water

Grey water, which means water from showers and taps is partly discharged ashore and partly overboard depending on the arrangements onboard a vessel and the reception facilities at ports. On most of the vessels, grey water goes through a sewage treatment unit, but on some older vessels, grey water is discharged directly to the sea via the holding tank. Black water, which is sewage from toilets is either discharged to the shore or discharged to the sea after going through a sewage treatment system. Currently international regulations allow cargo vessels to discharge both treated and untreated water to the sea depending on the vessel's location and sewage treatment plant certification. Our long-term target is that all wastewater generated onboard is discharged to shore reception facilities.

In 2024, ESL Shipping’s owned and pooled vessels delivered 30.2% (30.1% in 2023) of the black water and 18.8% (13.2%) of the grey water to shore reception facilities. In total, 20.4% (15.7%) of the wastewater was delivered to shore. While we aim to significantly increase the amount of wastewater delivered ashore and eventually discharge all wastewater ashore, we also acknowledge the challenge that some vessels are equipped with limited tank capacity for wastewater. Another challenge is that many ports do not have established reception facilities or practices for receiving wastewater. While we support tighter regulations for wastewater discharge to the sea, there needs to be functioning reception facilities at ports for vessels included in the waste fee.

Washing water from cargo holds

Our target is to discharge 50% of cargo hold wash water to shore by 2025 and achieve 100% by 2030 on all vessels we operate regardless of the ownership status. In 2024, we reached the 2025 target as vessels delivered around 63.1% of hold wash waters to shore compared to 43.5% in 2023. The increase was driven by a more proactive approach from operators, increasing the understanding and awareness onboard of the importance of the issue as well as improved data collection. As with the grey and black water, the challenge is that many ports do not have established reception facilities or practices for receiving washing water and the process can be time consuming and expensive.

Some older vessels have limited possibilities to store the washing water onboard if the wash is conducted at sea. Our 12 new Electramar-class newbuildings as well as 25,000 dwt vessels Viikki and Haaga are equipped with a dedicated collection tank for hold washing water eliminating the need to pump wash water overboard.

Generally, cargo hold washing water containing non-harmful cargo residues can be discharged to the sea whereas hold washing water containing harmful cargo residues must always be discharged to shore reception facilities. In a special area, such as the Baltic Sea, discharge to the sea is only permitted if both ports in a voyage are in the special area and there are no adequate reception facilities, and the residues are non-harmful to the marine environment.

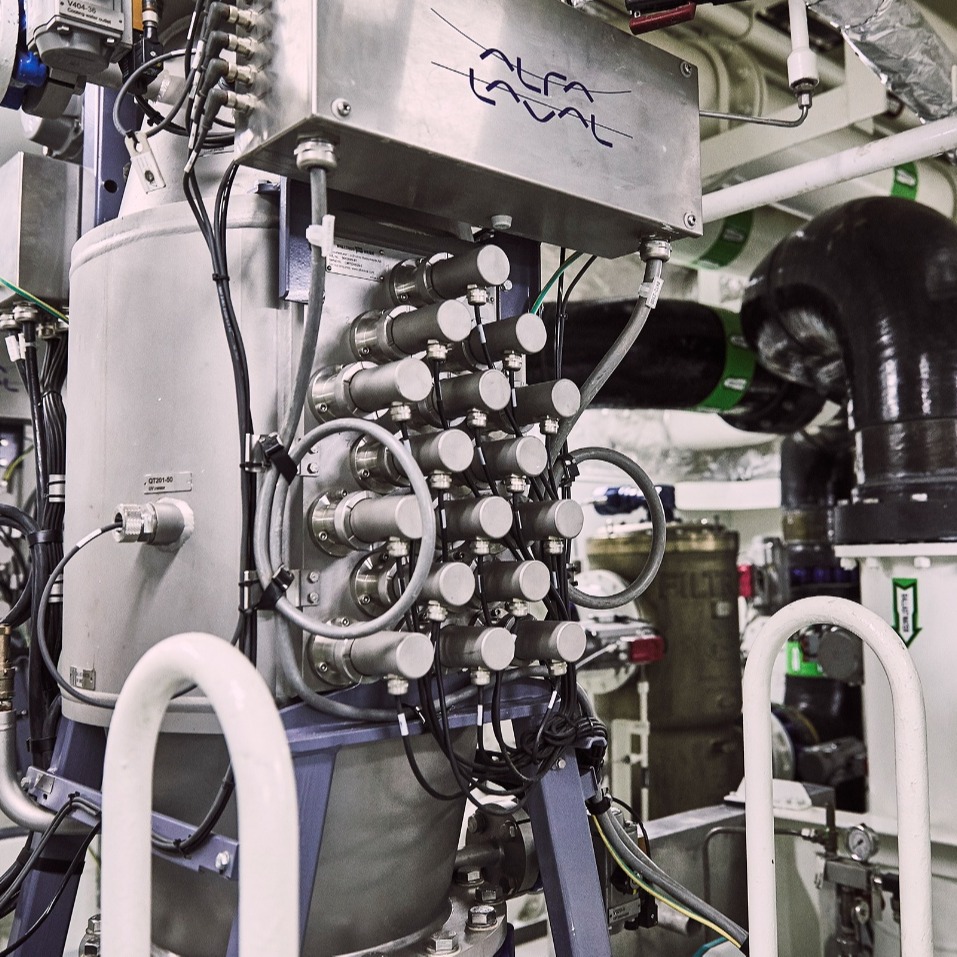

Ballast water management

Ballast water is essential for all types of vessels to ensure the stability and correct trim of the vessel. All our owned vessels are equipped with ballast water treatment systems (BWTS) according to the latest regulation. Some of the vessels have the United States Coast Guard – approved system enabling them to sail to and from the United States. The aim of the BWTS is to prevent foreign organisms from transferring into other sea areas in the vessel’s ballast water tanks. The last BWTS installations were completed in 2022. All our vessels have approved ballast water management plans.

Emissions are reported on EU and international level

Currently, the vessels’ carbon dioxide emissions are reported to two different systems: EU-led MRV and international, IMO-led DCS. The main difference is that MRV takes into account the voyages to and from EU-ports regardless of the vessel’s flag while IMO DCS takes into account all voyages of the vessel. In MRV-reporting, consumption at anchorage and at the port are excluded while IMO DCS takes into account those as well. ESL Shipping is responsible for reporting these figures for our own vessels. The figures submitted to MRV and DCS are verified by a third party, and Statement of Compliance is issued to each vessel.

Emissions of 4,000-6,000 dwt vessels operated by AtoB@C Shipping are reported to MRV from the beginning of 2025. In order to achieve a comprehensive picture of the group’s environmental footprint, we have calculated the emissions of these vessels as well and they are included in the figures presented in our Sustainability Rreports.

It is noteworthy that MRV figures take into account the weight of the cargo, which results in poor figures when lightweight cargoes, which fill up the hold, are carried. These cargoes include for example project cargoes, wood pellets and some steel products such as pipes.